Available now

We have machines ready to be delivered, today. Secure yours today.

Name

Price

Location

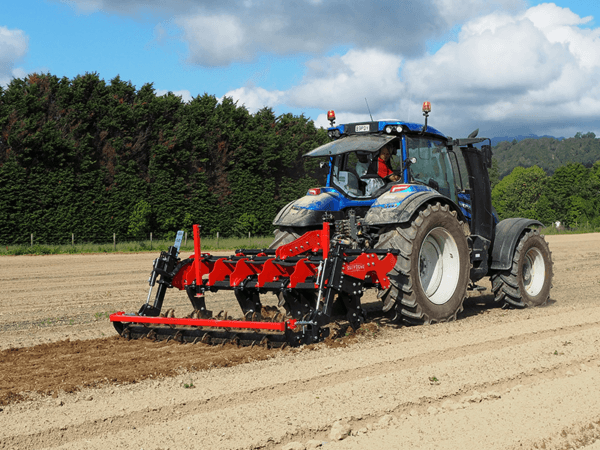

The SSDR Deep Ripper is your go-to, heavy-duty deep ripper ideal for work up to 600mm in heavy-going wet or dry conditions.

Its superior penetration and excellent lifting action will help turn around your paddocks like nothing before; minimizing passes, and allowing clogged paddocks to drain while maintaining moisture levels, saving you time and money.

We have machines ready to be delivered, today. Secure yours today.

Name

Price

Location

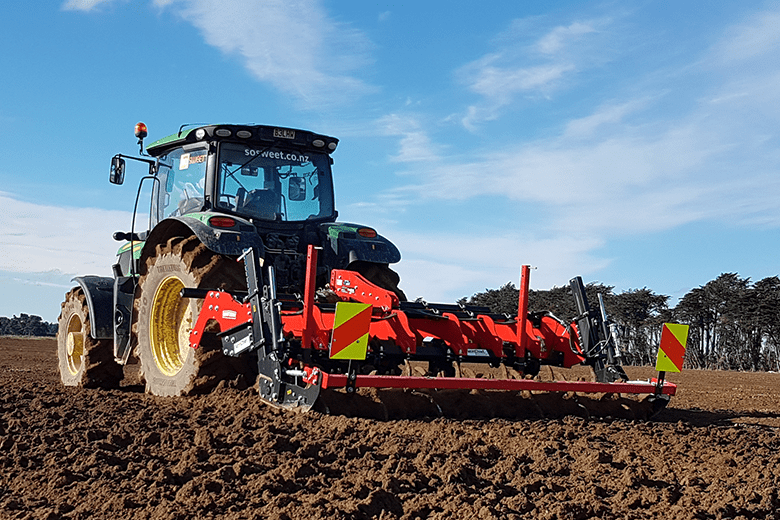

These next-gen heavy-duty cultivating rippers have technology that never takes a backward step. With their robust engineering and high specs, they’re recognized worldwide for their exceptional strength and reliability.

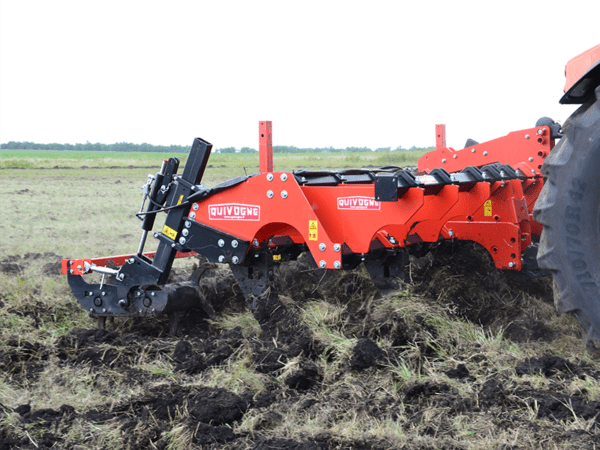

These effective and seriously tough customers break the pan, shatter the sub-soil and lift and loosen the ground, leaving an aerated but firm finish. Your paddocks are set up for further cultivation faster than any other rippers out there, helping you enjoy the prospect of improved yields, healthier crops and a better soil structure.

Their fully protected, highly engineered ripper legs provide an excellent lifting action even in tough-going soil, producing an aerated, incorporated soil structure, whilst the self-cleaning dual spiked rollers are perfect for working the top layer and creating a firm seedbed.

Choose to add on an alternative range of rear roller options from discs, packer rollers, finger tines and cage rollers.

Specifically Designed Ripping Legs

The SSDR’s fully protected ripping legs are fixed at a shallow 45-degree angle allowing for a deep penetration and an excellent lifting action. The reduced angle helps the ripper dig in deep whilst maintaining the same forward speed.

Its wide tine spacing is helpful for hard work in primary conditions that are either extremely wet or dry, providing excellent trash flow.

Dual Spiked Rollers

The specifically designed dual spike rollers feature curved, interlinked tines which include a self-cleaning action. Purpose-built for high-performance muddy areas, they are completely hydraulically controlled from the cab, allowing the operator to maintain the optimum working depth in variable conditions.

Heavy-Duty, Compact Build

A highlight of the SSDR’s design is the short and compact build, whilst still being heavy enough to be effective. The operator enjoys more ground pressure per m2 than other machines on the market whilst providing excellent contour following for the rear roller. Additionally, smaller and lighter tractors are able to easily lift and move the SSD making it a perfect option for a range of farms.

The heavy-duty build allows the SSDR ripper to work in the tough ground without warping or cracking, extending the lifetime of the machine and reducing repair time and costs, whilst helping increase ROI.

Model

Working width

Weight approx.

Working depth

Tine spacing

No. of tines

Rear Roller

HP Required

SSDR 5-250

2.50m

1620kg

600mm

430mm

5

Hydraulic double rear spiked roller

80+

SSDR 5-300

3.00m

2070kg

600mm

430mm

5

Hydraulic double rear spiked roller

100+

SSDR 7-300

3.00m

2174kg

600mm

430mm

7

Hydraulic double rear spiked roller

140+

SSDR 7-400

4.00m

2516kg

600mm

430mm

7

Hydraulic double rear spiked roller

200+

SSDR 9-400

4.00m

2687kg

600mm

430mm

9

Hydraulic double rear spiked roller

240+

SSDR 11-500

5.00m

3360kg

600mm

430mm

11

Hydraulic double rear spiked roller

350+